Comprehensive Guide to Metal Fabricators and CNC Lathe Machine Parts Suppliers

In the ever-evolving landscape of manufacturing and engineering, the role of metal fabricators has become more crucial than ever. As businesses strive for higher precision, efficiency, and innovation, the demand for premium CNC lathe machine parts suppliers continues to surge. At DeepMould.net, we specialize in delivering cutting-edge solutions that empower industries to thrive through excellence in metal fabrication and precision tooling.

Understanding the Significance of Metal Fabricators in Modern Industry

Metal fabricators are the backbone of modern manufacturing, transforming raw metal materials into intricate components used in various sectors including automotive, aerospace, construction, electronics, and defense. Their expertise lies in converting complex designs into real-world products through processes like cutting, bending, welding, and assembling.

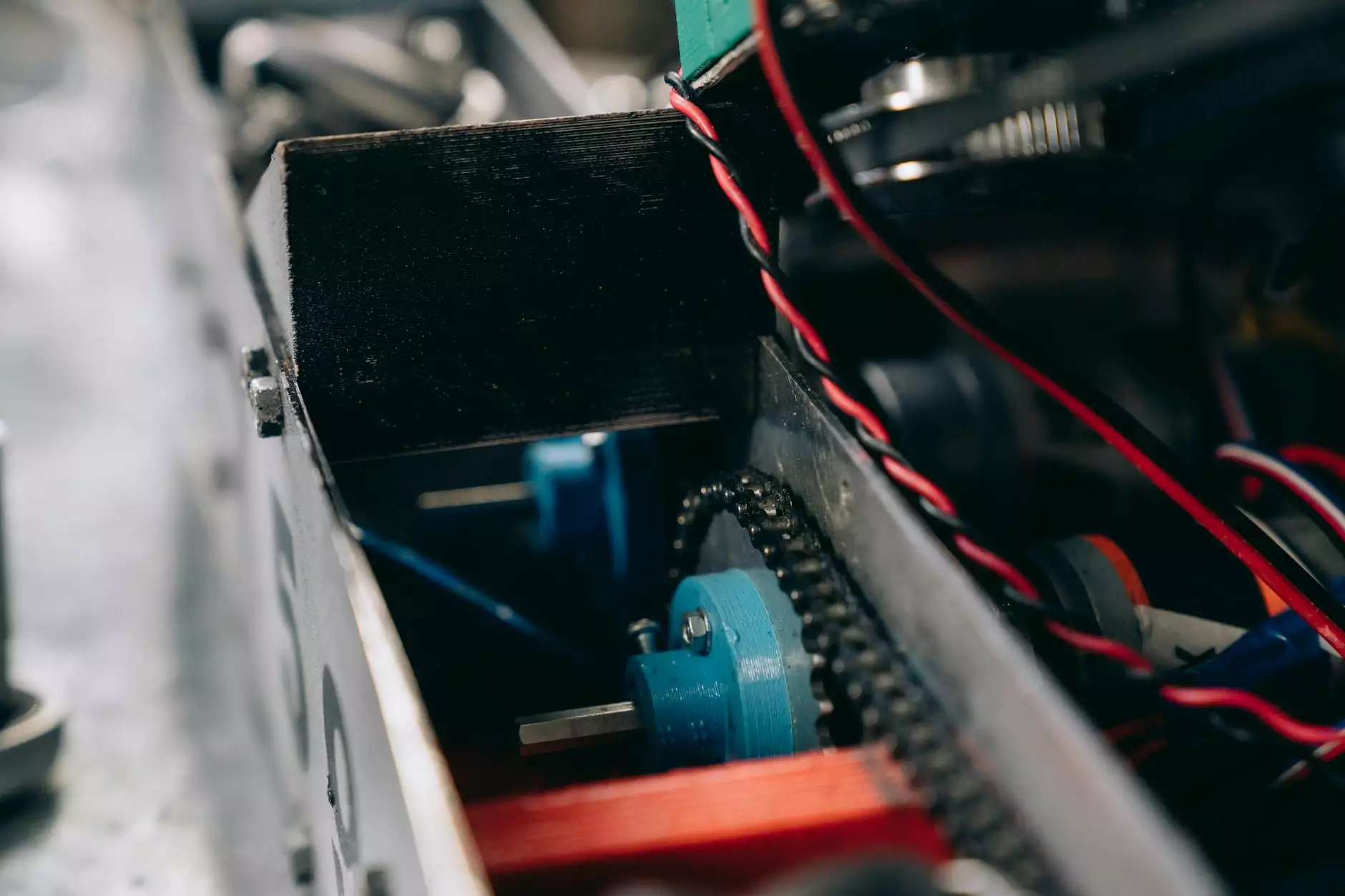

With technological advancements, the scope of metal fabrication has expanded dramatically. Today’s metal fabricators utilize advanced machinery such as CNC (Computer Numeric Control) machines, laser cutters, robotic welding, and 3D modeling to achieve unparalleled precision and efficiency.

The Role of Advanced Machinery in Metal Fabrication

- CNC Machining: Ensures high-precision manufacturing with minimal errors, essential for complex geometries.

- Laser Cutting: Provides clean cuts and detailed designs; ideal for intricate patterns and thin materials.

- Welding and Assembly: Combines components securely, ensuring durability and structural integrity.

- Surface Finishing: Enhances appearance, corrosion resistance, and wear properties of fabricated parts.

Why Precision Is Paramount in Metal Fabrication

In today's competitive market, the difference between a good product and a great product often hinges on precision and quality. Compact, accurate, and reliable manufacturing processes can significantly reduce costs associated with errors, rework, and downtime. The advent of CNC technology revolutionized metal fabrication by allowing manufacturers to produce parts with tolerances within microns.

Meeting stringent quality standards is vital, especially for industries like aerospace and medical devices, where even minor deviations can lead to catastrophic failures. Companies leveraging advanced metal fabricators equipped with state-of-the-art CNC equipment set themselves apart by delivering products that align perfectly with client specifications, regulatory standards, and safety requirements.

DeepMould.net: Your Trusted Partner in Metal Fabrication and CNC Supply Solutions

At DeepMould.net, we take pride in being recognized as one of the top metal fabricators with an extensive inventory of CNC lathe machine parts suppliers. Our commitment to quality, precision, and timely delivery makes us a preferred partner for industries demanding excellence.

Our Capabilities Include:

- Custom Metal Fabrication: Tailored solutions designed to meet specific project requirements.

- CNC Machining Services: High-precision turning, milling, drilling, and threading.

- Partnership with Leading CNC Lathe Machine Parts Suppliers: Ensuring availability of top-quality components.

- Surface Treatment & Finishing: Including anodizing, plating, polishing, and coating for enhanced performance.

The Critical Role of "cnc lathe machine parts suppliers" in Manufacturing Excellence

In the realm of CNC machining, cnc lathe machine parts suppliers serve as the foundation for achieving consistent quality and operational efficiency. The importance of reliable suppliers cannot be overstated; they provide components such as spindle assemblies, chucks, tool turrets, guides, and electrical drives that are essential for the smooth functioning of CNC lathes.

Choosing the Right CNC Lathe Machine Parts Suppliers

To maximize productivity and lifespan of CNC machinery, manufacturers must partner with suppliers who excel in:

- Quality Assurance: Offering parts that meet international standards such as ISO, ANSI, and CE certifications.

- Material Durability: Providing components made from high-grade alloys and composites suitable for demanding conditions.

- Precision & Compatibility: Ensuring parts are manufactured with tight tolerances that fit seamlessly with existing equipment.

- Supply Chain Reliability: Maintaining consistent stock levels and timely deliveries to minimize equipment downtime.

Benefits of Sourcing From Exceptional CNC Lathe Machine Parts Suppliers

Enhanced Machine Performance

High-quality parts improve the accuracy, speed, and efficiency of CNC lathes, leading to better surface finishes and tighter tolerances in finished products.

Reduced Maintenance and Downtime

Reliable components mean fewer breakdowns, lower repair costs, and extended machine lifecycle, saving businesses significant operational expenses.

Optimized Production Workflow

Consistent supply of compatible spare parts reduces operational delays, allowing production schedules to stay on track and meet deadlines.

Cost-Effectiveness

Although premium parts might come with a higher upfront cost, they offer greater longevity and reliability, resulting in lower total cost of ownership over time.

DeepMould.net’s Commitment to Excellence in CNC Components Supply

Our network of cnc lathe machine parts suppliers boasts partnerships with globally recognized brands and manufacturers. We meticulously select our suppliers based on their reputation for quality, innovation, and adherence to international standards.

By choosing DeepMould.net, clients benefit from:

- Extensive Inventory: Wide-ranging parts suitable for various CNC lathe models and applications.

- Technical Support: Expert consultation to identify the best components for your specific needs.

- Competitive Pricing: Cost-effective solutions without compromising on quality.

- Fast Delivery: Ensuring minimal disruption to your production line.

Future Trends in Metal Fabrication and CNC Machining

The future of metal fabrication and CNC machining is bright, driven by innovations like automation, artificial intelligence, and additive manufacturing.

Automation and Industry 4.0

Integrating smart systems with metal fabricators streamlines operations, improves accuracy, and enables real-time monitoring and predictive maintenance.

Advanced Materials

The development of newer alloys and composite materials expands the possibilities for lightweight, high-strength components in aerospace, automotive, and medical sectors.

Sustainable Manufacturing

Eco-friendly processes, recyclable materials, and energy-efficient equipment are becoming standard, aligning industry growth with environmental responsibility.

Conclusion: Elevate Your Manufacturing Plant with the Right Partners

In conclusion, whether you are a seasoned manufacturer or a newcomer seeking to establish a foothold, understanding the importance of metal fabricators and cnc lathe machine parts suppliers is fundamental to achieving operational excellence. Partnering with an experienced provider like DeepMould.net ensures access to superior products, technical expertise, and reliable service. Embrace the future of manufacturing by prioritizing quality, innovation, and strategic supplier relationships.

Investing in the right metal fabrication solutions and CNC components not only boosts productivity but also sustains competitiveness in a global marketplace. Stay ahead with cutting-edge technology, trusted partnerships, and a commitment to continuous improvement.

Connect With Us Today

Explore our full range of services and discover how DeepMould.net can elevate your manufacturing processes. Our team of experts is ready to assist you in finding the best metal fabrication solutions and cnc lathe machine parts to meet your business objectives.